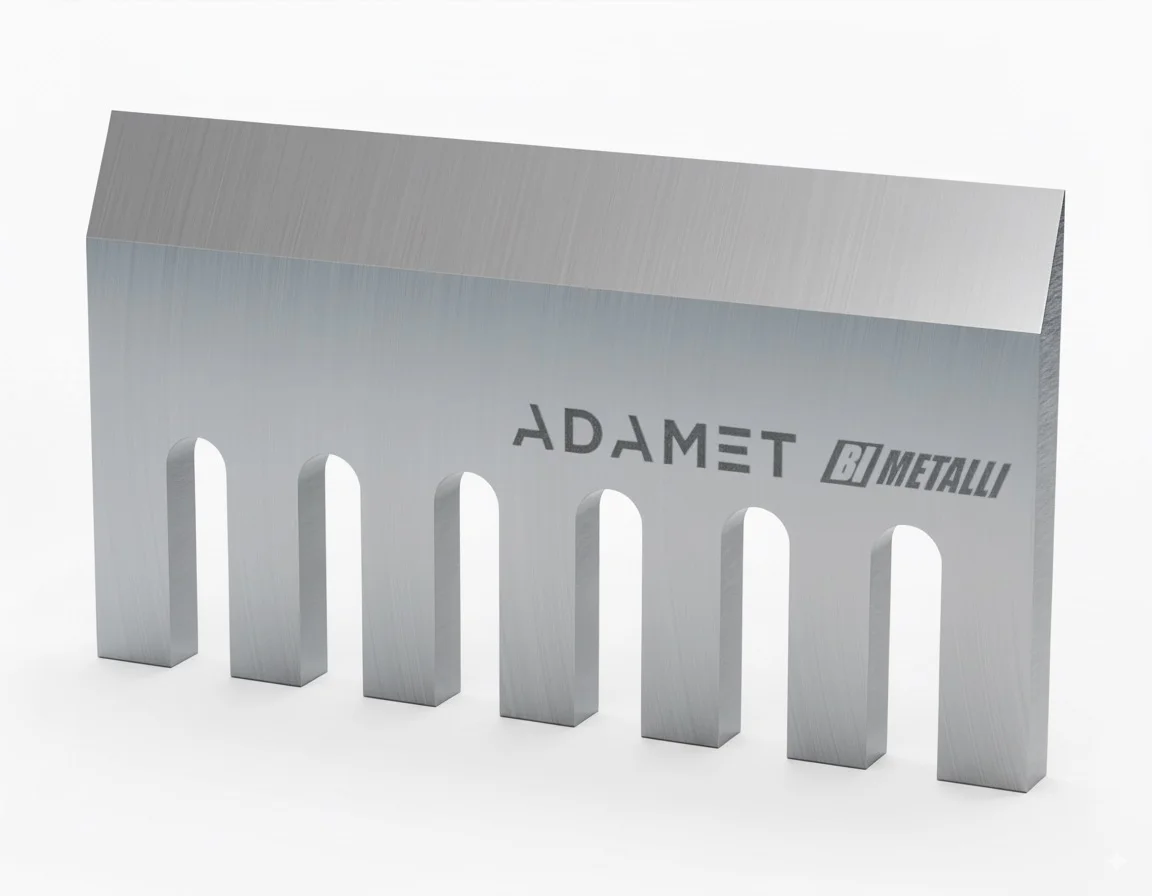

Industrial Blades for Plywood Production

Blades for plywood production and veneer processing. Precision solutions for veneer lathes, planing and guillotines.

Blade Selection

Veneer Lathe Blades

Blades for cutting veneer mats in veneer lathe machines. Optimized precision and clean cut quality.

Veneer Planing Blades

Bimetal steel: high-speed steel cutting edge and flexible support metal for special applications.

Guillotine Blades

Straight blades for cutting veneer sheets in guillotines. Clean cut without cracks.

Technical Features

Wear Resistance

Through-hardened steel, hardness 58-62 HRC. Service life up to 15,000 m.

Materials

S5 steel for softwood, H13 for hardwood, bimetal for special applications.

Tolerances

±0.005 mm dimensional tolerances, Ra ≤0.25 μm surface roughness.

Material Options

S5

Tool steel grade for softwoods. Hardness 58-60 HRC, good toughness to hardness ratio.

H13

Hot work steel for hardwoods. Hardness 54-58 HRC, better toughness in hard wood species.

BI-METAL

HSS cutting edge (64-66 HRC) and shock-absorbing body (45-50 HRC).

Technical Specifications

Dimensions

Length: 500-6000 mm

Width: 20-250 mm

Tolerance: ±0.005 mm

Surface Quality

Roughness: Ra ≤0.25 μm

Straightness: ±0.2/3000 mm

Treatment: Through-hardened

Compatibility

We supply blades for machines from manufacturers including: